Guide to Fiber Connector Endface Polish Types: UPC vs APC

Published on April 17, 2020 by Jace Waechter

Ultra Polished Connector (UPC) & Angled Polished (APC) connector: what’s the difference?

When talking about fiber optic products like trunk assemblies, patch cords, or single-mode jumpers, eventually UPC connectors or APC connectors will enter the conversation.

This may lead some people to be curious. For example, what’s the difference between an LC/UPC connector or an LC/APC connector? Are the two connector types compatible? And finally, what’s the cost-effectiveness of the two?

Eight Degrees of Separation

The main difference between UPC connectors and APC connectors is the fiber end face. An APC connector end face has an eight-degree angle while the UPC connector has no angle. How the end face is shaped affects how light is reflected. Return loss, expressed in negative decibels (dB), is the measurement that industry experts use to determine how much light is reflected. The higher the return loss, the stronger the signal returned. It is generally the goal in communications to have as little return loss as possible.

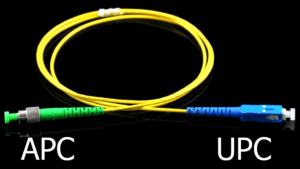

Another difference between UPC and APC is the industry standard color. The UPC connector is usually blue, while the APC connector is usually green.

Ultra Physical Connector (UPC)

Building on the convex end face from the now outdated PC connectors, UPC connectors utilize extended polishing methods which creates a finer fiber surface finish. The flat fiber end face reflects light directly back towards the source, resulting in -50dB or lower reflections. The relatively low return loss allows for a more reliable signal for digital TV, telecommunications, and data centers, where UPC dominates the market today.

Angled Physical Connector (APC)

Although UPC connectors have low return loss, there are cases where it is not low enough to meet the needs of an application. Today’s high bandwidth broadband connections and RF over fiber are examples of applications that require very low reflections to maintain high quality of service. To solve this problem, engineers need a connector with lower return loss that exists in the same form factor they are already using.

Enter the oddly angled APC connector end face. By angling the ferrule end face eight degrees, light is reflected into the cladding instead of directly back to the source. Because of this, APC connectors can support a whopping return loss of -65dB or lower. Traditional connectors like the SC and LC, which have been in the market for years, are now readily available with the 8 degree endfaces.

Applications

Photo of Green SCAPC connector & Blue SCUPC connector

If your application is sensitive to return loss then we suggest using APC connectors. For instance, in applications that operate in higher optical wavelength ranges (above 1500 nanometers) like those used for RF video signals, reflected light can damage the signal source. That is why we see APC connectors being widely deployed in service provider networks and FTTx applications.

There is no doubt that the optical performance of APC is better than UPC. However, in today’s market, cost and simplicity should be taken into consideration. UPC connectors are less expensive and are still a reliable choice for less sensitive digital systems. UPC connectors might be a better choice if the cost budget is of equal importance to optical performance. That is why UPC connectors continue to lead the market in fiber networks.

Please keep in mind that APC and UPC connectors CAN NOT be plugged into each other. This is a common misconception — they are not compatible to be used together.

Megladon offers a variety of standard and custom-made fiber solutions with LC, SC, ST, FC, and MPO connectors (UPC and APC polish). You can create your custom-made fiber solution with our Custom Cable Configuration Tool.